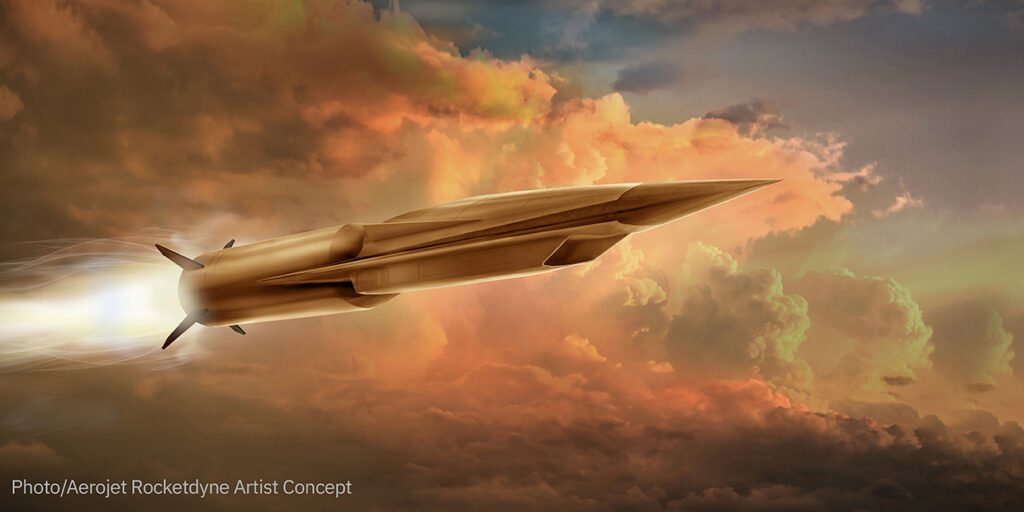

HUNTSVILLE – A successful test of a next generation large solid rocket motor answered two issues for Aerojet Rocketdyne.

The rocket engine manufacturer said the test for the eSR-19 validated advanced motor technology and showed the production maturity of its new and upgraded facilities in Camden, Ark., and Huntsville.

The recent design verification test of the eSR-19, funded by Aerojet Rocketdyne, highlights the company’s evolution of large solid rocket motors that can function as multiple stages for defense and space applications.

“Our teams building our next generation large solid rocket motors are incorporating innovative materials and applying efficient manufacturing processes,” said Eileen P. Drake, Aerojet Rocketdyne CEO and president. “We continue to invest in the future – in modern facilities and a highly skilled workforce – to design and produce the advanced technology needed to power defense across multiple domains.”

The eSR-19 motor was designed and fabricated in Huntsville and cast and cured in Camden, Ark. The test was conducted by Air Force Research Laboratory and Aerojet Rocketdyne personnel at an AFRL test facility at Edwards Air Force Base, Calif.

Weighing nearly 15,000 pounds and measuring 52 inches in diameter, the eSR-19 is a large solid rocket motor program to upgrade the legacy SR-19 motors originally used in the Minuteman II. This capability demonstration is directly applicable to legacy SR-19 applications, and is a building block for multiple systems under development today.

The recent test of the eSR-19 builds upon last year’s successful test of the eSR-73 demonstration motor, which served as a pathfinder for producing and handling large solid rocket motors at the company’s upgraded Camden facilities.

Aerojet Rocketdyne has produced large solid rocket motors for critical defense and space programs for decades. The company transferred the production to its Camden and Huntsville sites as part of its Competitive Improvement Program, which increased affordability and positioned the company for growth.