HUNTSVILLE — Teams at the Marshall Space Flight Center have completed applying a spray-on foam insulation to the launch vehicle stage adapter (LVSA) for the Artemis III mission, NASA announced.

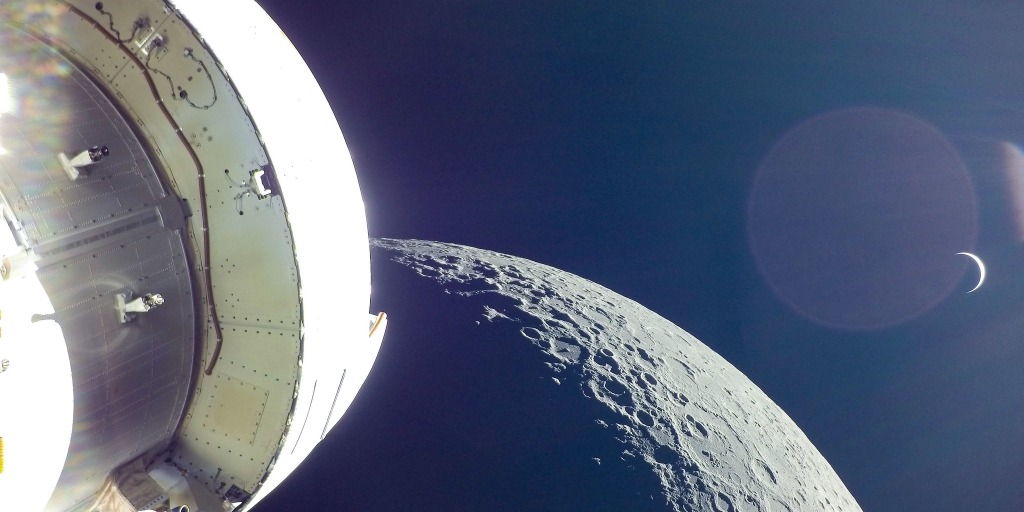

The LVSA is a cone-shaped piece of hardware that connects the SLS rocket’s upper and lower stages and partially encloses the engine of the interim cryogenic propulsion stage.

The spray-on foam insulation protects the rocket’s hardware from the extreme temperatures, forces, and sounds it’ll experience during launch and ascent.

Unlike other parts of the mega rocket, the thermal protection system for the LVSA is applied entirely by hand using a tool similar to a spray gun. It is the largest piece of SLS hardware to be hand sprayed.

Teams started applying the thermal protection system in March.

The LVSA will be used for Artemis III, the mission that will land the first woman and first person of color on the lunar surface. The craft is fully manufactured at Marshall by NASA, lead contractor Teledyne Brown Engineering, and the Jacobs Space Exploration Group’s ESSCA contract.