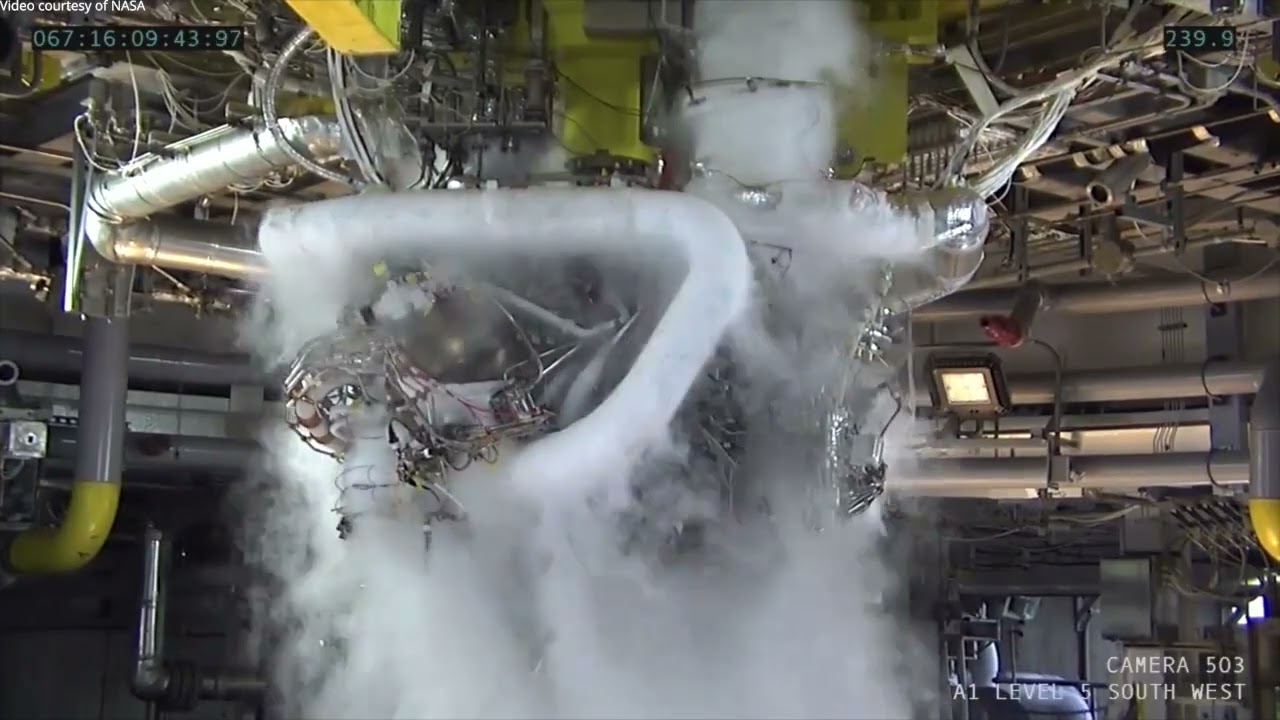

BAY ST. LOUIS, Miss. — NASA’s testing for redesigned RS-25 engines to be used on future Space Launch System missions continued with a full-duration hot fire at NASA’s Stennis Space Center, near Bay St. Louis, Miss.

The test, conducted on the Fred Haise Test Stand at Stennis, was the third of the year and part of an ongoing certification hot fire series. It also was the third test since an upgraded nozzle was installed on the RS-25 engine just prior to a Feb 8 hot fire.

The redesigned engines provided by lead SLS engines contractor Aerojet Rocketdyne will be used on Artemis flights to the moon, beginning with Artemis V.

(NASA/Stennis photo)

“Early indications are that the nozzle is working well,” said Mike Lauer, deputy program manager of RS-25 engines at Aerojet Rocketdyne. “Even though we changed manufacturing methods, we did not want to radically change the performance of the nozzle.

“We are very pleased that the nozzle appears to be performing very much in line with our previous history.”

Operators fired the RS-25 engine during the test for a scheduled 520 seconds and up to 113% power level. During missions to the Moon, engines fire for about 500 seconds and up to the 111% power level to help SLS lift the Orion spacecraft and other payloads to orbit. With added seconds and the increased power level during ground tests, engineers can learn more about engine performance and provide a margin of operational safety.

The nozzle, or bell-shaped part at the bottom of the RS-25 engine, helps generate thrust by ejecting the engine’s exhaust at maximum speed to propel SLS to space. It is one of multiple upgraded components on the redesigned engine and also critical in ensuring efficiency by using a minimum amount of propellants, or fuel, to generate thrust and help propel the rocket to space. The nozzle is one reason the RS-25 is one of the most fuel-efficient rocket engines in the world.

Over the course of the storied history of the RS-25 engine, many components have gone through changes or upgrades. One component that mostly went unchanged was the nozzle.

For redesigned RS-25 engines, however, a team focused on re-engineering every part of the nozzle. This included using precision machining to improve production of the more than 1,000 tubes that comprise the nozzle wall. These tubes are critical in flowing super-cold liquid hydrogen to keep the nozzle cool. The team also is using 3D printing to manufacture selected nozzle parts.

Upgrades to the nozzle include a new type and amount of insulation, which is a critical consideration since the RS-25 engines are exposed to more heat during SLS launches than previous space shuttle missions. SLS features four RS-25 engines instead of the three main engines used for the space shuttle and the proximity of the RS-25 nozzle to the SLS solid rocket boosters is closer than on the space shuttle.

The goal of the upgrades is to streamline the nozzle production process, while making it more cost efficient and still achieving the same performance level as with previous RS-25 engines. While new manufacturing methods have been incorporated into the production of the nozzle, the shape, length, and diameter remain the same.

Sixteen main engines remained from the shuttle program. All were modified and tested at NASA Stennis for use on the first four Artemis missions.