When Walls Machine Co., a precision machine and tool company located in Owens Cross Roads announced they had hired Danny Light as its new director of Business Development, I was curious to know whether the precision machine and tooling industry was facing the same challenges other manufacturing-related businesses are facing in terms of a workforce and materials shortages.

What I discovered is that the machine and tooling industry was more than the sum of its parts to the skilled workers who make them, and that puts a whole new perspective on how complex assemblies work.

“It makes you want to emphasize that in today’s society, everything does not come from Walmart,” Danny says as I blush with guilt.

How many times have I been putting together a table, a desk or a bookshelf and been relieved to find how perfectly all the parts come together, the screws and bolts and brackets and holes all fit together just right, while deep down, all I care about is how the finished product looks in my home or office.

“I constantly remind my kids that what you buy at Walmart was made somewhere else – things don’t come all put together like that,” Danny continues. “We take for granted what it takes for a helicopter to fly across a field. Every rocket engine has multiple components and precision machined parts made all over the world and at some point, they all come together to make that rocket work.”

Quality precision machine shop technology makes it possible.

Every blade on a new riding lawnmower, every exhaust port on a vacuum cleaner, even the little red plastic on-and-off toggle switch on a computer or kitchen appliance has been meticulously tooled somewhere in the world and made its way home to that helicopter, that car, that video game or that computer.

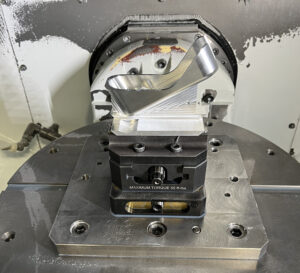

After touring the impressive facility and holding a meticulously tooled “thing” in my hands, I am fascinated by its perfection. After having been cut meticulously into something I do not recognize, I notice it is all shiny as well because it has been anodized. Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish, a process that has to be cut so precisely, the thickness of the coating must meet the appropriate tolerance, so it fits with precision.

“Almost everything Walls Machine Co. makes goes on a helicopter,” Danny tells me as I shift the shiny part from hand to hand.

“We know that what you are holding in your hand goes on an Apache helicopter, a hinge part used for mounting guns in their turret, but sometimes, we just don’t ask,” he laughs.

Holding the precision tooled hinge in my hands, I recall the handful of times I have had an opportunity to climb up into a Blackhawk and Apache helicopter to look around. I do not think I will ever do it again without seeking out that single bracket used to mount the Apache’s guns on the chin turret made at Walls Machine Co. in Owens Cross Roads!

Yes, Walls Machine Co. like most businesses have been affected by material and workforce shortages, but after a tour of the facility and holding their incredible work in my hands, it is clear Walls Machine Co. is better served by focusing on the millions of dollars they have invested in cutting edge CNC machines and tooling capabilities, than on their physical size.

Established in 1993, Walls Machine Co. when compared to the average corporate office is a small shop, but in the world of precision machinery, Danny Light said it is almost unheard of to have 10 to 12 full-time employees.

Danny has 35 years in industrial sales and networking in the machine and tool business, and his strategy is to expand the company’s favorite hunting hole by actively seeking another million dollars in wins from Request for Proposals (RFPs) that have never been pursued before.

“That is how you grow this business,” he says. “Wall Machine is primed for explosive growth and opportunity in the Huntsville market.”

With two additional acres of land on which they can quickly build, Danny is letting owner Jeremy Walls focus on what he does best as a skilled parts maker, while Danny focuses on what he does best – networking and building their current customer base.

“Currently, we have several contracts for services to the aerospace industry, the military, and commercial industries,” Danny explains. “Many of our current customers are subcontractors, so our parts are already going to big prime contractors like Boeing and others in the military world, but machine shops still have to earn their way in this business.

“I am going after bigger contracts with big prime contractors like Lockheed Martin, Boeing, Blue Horizon, Blue Halo, and Radiance Technologies. That is the only way to grow a machine business today. Sitting back and waiting for business to come to us is not a winning strategy.”

It is a very competitive business too and a successful machine shop doesn’t stop at making perfect parts.

Danny tells me there are over 60 machine shops in the Huntsville area due to the volume of work from NASA and the aerospace manufacturing companies. That includes manufacturers who do enough volume to have an in-house quality precision machine shop and a couple of large shops owned by the federal government.

“Our work is about being smart when it comes to buying materials, cutting costs wherever we can, and saving as much material from waste as possible,” says Travis Pruyne, head of the CNC department at Walls. “The competition is doing the same thing when they bid a job so to be competitive, we have to be as efficient as possible.”

That is not always as easy as it sounds considering pervasive supply and materials shortages.

And the situation is complicated by the fact all suppliers for the military must be approved for doing business with the government, so while the shortages have trickled down, the stringent requirements make it all the more challenging.

“How do we combat it?” Danny asks rhetorically. “Sometimes the client provides materials, but in bidding jobs, we look for accredited and certified approved vendors, some of whom we know are harboring materials or may have the material, even though it will cost more.”

But Travis admits that can be risky.

“You don’t want to lose a bid, but once we say a job looks like it is going to cost this much,” explains Travis. “Then you must hope those vendors come through or you can find yourself losing thousands of dollars a day if they come back and say, sorry – we thought we would have this material, but now we do not.”

Since the shortages started, Walls has had to rebuild contracts to allow for lost time due to the inaccessibility of certain materials.

I am handed a $300 block of raw Teflon and I can’t help remembering my grandmother’s first non-stick Teflon frying pan … but I digress among the myriad shapes and sizes in which raw materials come as I walk around blocks, slabs, and even rolls of raw metal and plastic.

“We have to look at our options and calculate whether it is more efficient and economical to buy aluminum for a certain project in a sheet, a slab, a block, or in this case a rod,” Travis explains.

Just recently they faced exactly that dilemma.

“The aluminum material we wanted for these helicopter brackets comes in square blocks, but it was not available,” he states. “We bought it in rods and slabbed it off ourselves to the point where there would be less waste. It was our best option to get the most product with the least amount of waste since our preference wasn’t available.”

And when bidding on jobs, the competition is facing the same thing and doing those same calculations. It forces them to decide whether it is better to make parts with less waste using multiple blocks of aluminum for $300 a block, or a $3,000 sheet of aluminum with better cost savings.

And here is a shocker – the metals industry is one of the oldest and most successful recyclers in history!

That slab of aluminum Travis purchased last week might have been a car frame a month ago, thanks to large scrap metal mills that collect giant piles of metal and smelt it down to be reused or remanufactured. Even machine chips rejected in the milling process are sold back to the industry as waste and refurbished for pennies on the dollar.

“All the materials have to be thought out, technicians have to know what they are doing, and the programmers who set it up have to be experienced,” Travis says. “While we are short on experienced and qualified workers, it doesn’t matter how much metal material I can find if I don’t have the people to tool it. And if I have to train, that means I have to stop, and that affects deadlines.”

So, yeah. Both Danny and Travis admit a lot more goes into a precision machine shop than people realize.

“But that is not going to stop Walls Machine Co. from explosive growth going forward,” Danny says.

Don’t miss out! Subscribe to our email newsletter to have all our smart stories delivered to your inbox.